Other EE air-conditioning technologiesAnti-ultraviolet filmTechnology outline:Windows in buildings can admit daylight into the indoor environment. However, daylight is always accompanied by solar heat gain, which can increase the cooling load of air conditioning system. The anti-ultraviolet film is a thin coating on the window glass. The coating can reduce heat gain and at the same time maintain a certain level of daylight to be transmitted into the indoor environment. How it can save energy:The anti-ultraviolet film can reject solar heat and subsequently reduce the energy consumption of the air conditioning system due to the solar heat gain. In addition, the use of this film can avoid the problems of glare and excessive brightness. People can utilize more natural daylight. As a result, the demand on artificial lighting can also be reduced. How much energy can be saved?According to one of the related case studies in Hong Kong, 30% of the diffuse solar radiation and 50% of the direct radiation can be rejected by using the film coating, while the visible transmittance of the film could be maintenance at around 76% [1]. However, the energy saving of this technology depends greatly on the window area of the building, orientation of the windows and the extent of applications. The results of the case study are for reference only. To view project example, please click here Electronically-Commutated Permanent Magnet Motor (ECPM)Technology outline:The ECPM is an ultra high efficiency programmable brushless DC motor utilizing a permanent magnet motor and a built-in inverter. ECPMs behave like classic DC motors, as their speed is proportional to the voltage and the torque is proportional to the current. They are variable speed motors inherently. The speed is controlled via pulse width modulators (PWM) which controls the voltage. The PWM switching is superimposed on the commutation switching, therefore requiring no additional hardware. How it can save energy:

The variable speed operation matches the speed required by the application, enabling pumps, fans and compressors to efficiently meet partial loads. How much energy can be saved?The typical applications in HVAC of ECPM are fans and blowers. The energy saving by using this technology is ranging from 10% to 30% [2]. Variable Refrigerant Volume (VRV)Technology outline:Variable Refrigerant Volume (VRV) sometimes refer to as "Variable Refrigerant Flow" (VRF). This is a kind of multi-split HVAC system which one external condensing unit / heat pump is connected by refrigerant pipework to several indoor cooling / cooling and heating units. The volume or flow rate of refrigerant is accurately matched to the required heating or cooling loads therefore saving energy and providing more accurate control. How it can save energy:If part of a building requires cooling and other area requires heating, the heat rejected for the required cooling can be recovered to provide heating in the other area. In addition, if the temperature in a specific zone is lower than the set point temperature, the indoor unit will shut down and the load of the outdoor unit can be reduced. How much energy can be saved?The energy saving of VRV system is very much depending on its application. It is no definitive statements about thier actual savings. The Coefficient of Performance (COP) of VRV can up to 3-4 under test conditions. Variable Speed Drive (VSD)Technology outline:Almost all pump and fan systems are sized to handle maximum load under worst case conditions and then leaving them to run at full power. By using Variable speed drives (VSDs) to vary the flow according to the actual demand can save a significant amount of energy. VSDs are electronic devices which can be attached to an induction motor with a control mechanism. They can be incorporated into any motor with a variable load, but the most common applications are pumps and fans. How it can save energy:A VSD can be regarded as a frequency converter rectifying AC voltages from the mains supply into DC, and then modifies this into a AC voltage with variable amplitude and frequency. The motor is thus supplied with variable voltage and frequency, which enables infinitely variable speed regulation of three-phase, asynchronous standard induction motors. As the speed of the fan or pump is reduced, the power required will reduce with cube of the speed. This level of potential saving makes the use of VSD a cost-effective investment in energy efficiency which can be considered for motors. The followings are some of the typical examples of VSD application in A/C system. Applications in HVAC systems:(a) Primary Air handling Unit (PAU)

Conventional Primary air Handling Units (PAUs) usually pre-treat outdoor air at a constant air volume (i.e. CAV). The PAUs supply air to different areas in the building at a constant air flow rate of full load condition, disregard the actual demand. This will waste energy because the PAUs operate at part load instead of full load in most of the time.

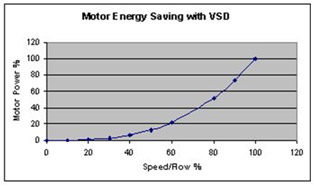

Demand control on PAUs using carbon dioxide (CO2) provides unique opportunity to resolve the problem of how to reduce energy costs while optimizing indoor air quality. CO 2 control is best applied to spaces with variable or intermittent occupancy. Building Services Research and Information Association (BSRIA) Technical Note (TN) 12/94 suggests that significant energy saving may accrue from the use of CO2 control. (b) Variable Air Volume (VAV) Air handling UnitVariable Air Volume (VAV) systems typically bring conditioned air from PAU and returned air from the air-conditioned space into Air Handling Units (AHU). The air is delivered to each zone through ductworks and individual VAV terminal boxes where temperature sensor is located. Set point temperature is maintained by closing or opening of VAV box. When setpoint temperature is reached, VAV box will be modulated to a close position and consequently the pressure in the ductwork is rose. In this way, VSD can be utilized to decrease the speed of the AHU fan after receiving the pressure level signals from the static pressure sensor in the air duct to provide the flow and pressure required by the system. (c) Secondary chilled water circuitIn chilled water system, the primary loop consists of primary pump sized to circulate the chilled water through the chiller and the rest of the primary piping loop. The secondary chiller water loop, which consists of secondary pump, is a variable flow system. Chilled water is circulated by the secondary pump through the control valves and cooling loads connected to the circuit. However, most of the control valves in the circuit are not fully open because of part load in most of the time. Therefore, the chilled water flow in the secondary water loop can be regulated by VSD to handle the chilled water requirement by the cooling load, thus to save energy. How much energy can be saved?VSD can bring significant motor energy saving. Since power is proportional to the cube of speed, when the motor speed is reduced to 50% of the rated value, the load requires only 12.5% of the maximum power.

To view project example, please click here Further sources of information:EMSD website, Advance energy saving technologies: This web page has hyperlinks which may transfer you to third-party website.http://www.emsd.gov.hk/emsd/eng/pee/ em_pub_2.shtml

Reference

|