Water-side Systems/Equipment

- Scale control technologies in water-side system

- Heat recovery equipment for water-side equipment

- Thermal energy storage

- Water-cooled air conditioning system

Scale control technologies in water-side system

Technology outline:

In a water-cooled air conditioning system, heat is rejected from the refrigerant to the cooling water in the condenser. The impurities in the cooling water circuit are accumulated, and thus the scales and deposits are built up in the condenser tubes, creating fouling problems on the condenser heat transfer surfaces. This reduces the heat transfer efficiency of the condenser and thus increases chiller energy consumption.

(a) Automatic tube cleaning system

The automatic tube cleaning system is usually installed as an integral part of the condenser. The system cleans the condenser tubes by circulating a number of soft sponge balls through the tubes at pre-set time interval. Since the balls are soft and light in nature, they will not cause any damage to the condenser tube surface and can be carried easily through the tubes by the flowing of water.

To view project example, please click here.

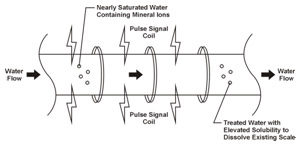

(b) Dynamic-type pulsed-power devices (PPD)

The principle of the PPD is that when water containing scaling materials is passed through a magnetic or electromagnetic field, the electrochemical nature of the ions of complex minerals is changed and precipitation will occur. The net effect is that the hardened minerals are changed from a scale (calcite crystals) to a suspended powder (aragonite crystals), which solubility is increased in water.

PPD consists of two components: the transformer panel and the coil and pipe reaction chamber. The transformer panel brings line voltage down to the operating voltage of the system. The reaction chamber sets up a pulsing, coil resonating (or "ringing") harmonic field across the flow gradient. The electromagnetic field lowers the negative electric charge on the surface of particles within the solution, giving the particles a more neutral charge allowing them to coagulate easier.

Dynamic-type pulsed-power devices

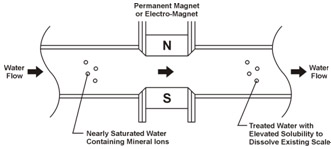

(c) Static-type magneto-hydrodynamic devices (MHD)

The theory behind the MHD is similar to the PPD. MHD also generates electromagnetic field in the flowing water inside the chilled water circuit to increase the solubility of complex minerals in water. MHD employs either a permanent magnet or an electromagnet. It exposes the flowing water contained charged ions of complex minerals to steady magnetic field of chosen direction and field strength. The interaction of the charged ions in the flow and the magnetic field creates an electrical current flow in the water flow.

How it can save energy:

The scale control system cleans the heat exchanger surface and eliminates tubing fouling by removing debris from tube surfaces. This can lower the water flow resistance and improve the heat transfer efficiency of the condenser tubes. Thus the chiller efficiency can be enhanced.

How much energy can be saved?

Even a thin scale of 0.8mm thick can increase energy consumption by nearly 10% [2]. According to some case studies in Hong Kong, the energy saving by adopting the scale control system in water-side air conditioning system can is around 10 to 15%.

Heat recovery equipment for water-side equipment

Technology outline & how it can save energy:

(a) Plate Heat Exchangers

Plate heat exchanger uses metal plates to transfer heat between two liquids. The major advantage of this type of heat exchanger is that the liquids are exposed to a much larger surface area. This facilitates a higher rate of heat transfer between the liquids. Due to the high heat transfer efficiency, plate type heat exchangers are usually much smaller than tube and shell type heat exchanger with the same heat transfer capacity. The figure below shows a typical plate heat exchanger.

A plate heat exchanger

(b) Heat recovery chiller

In the usual operation of water-cooled chiller, a significant amount of heat is rejected from the condenser. This wasted heat can be reclaimed for other applications such as domestic hot water preheating, air or space reheating in the air handling units. The figure below shows the schematic diagram of a chilled water system with heat recovery chiller.

Thermal energy storage (TES) system

Technology outline:

Thermal energy storage (TES) refers to technologies that store energy in a thermal reservoir for later re-use. The energy is usually stored in the form of ice. Therefore, the system is commonly refereed to “Ice-storage system”. The principal application of the TES system is the production of ice during off-peak periods of electricity demand (ie. at night) which is then used to cool environments in daytime to meet the air conditioning needs. As a result, the system helps shifting the power consumption at peak hours during daytime to the off peak hours during nighttime, thus reducing the electricity consumed by the air conditioning system during the peak hours.

How it can save energy:

It is commonly understood that TES system can reduce peak demand of a chiller plant and hence lower the demand charge of the electricity bill. However, it is not usually considered as an energy saving equipment. In theory, TES system could make chiller more efficient because it works at lower condensing temperature during night time when the ambient temperature is lower. In practice, this advantage can be compensated by the heat losses while making and melting the ice (ie. The phase change). To view project example, please click here.

Water-cooled air conditioning system

Technology outline:

Building air conditioning system works on refrigeration principles, using cooling medium to lower the indoor air temperature. The heat absorbed by the refrigerant is then rejected to the outdoor environment either directly to the atmosphere (i.e. air-cooled), by evaporation through cooling towers, or by seawater discharge to the sea (i.e. water-cooled). The last two heat rejection methods can be categorized as water-cooled method because they use water (either fresh water or seawater) as a heat rejection medium.

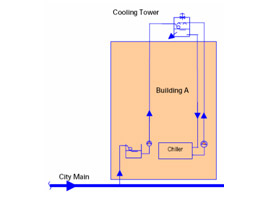

a) Cooling Tower Scheme

The air conditioning system uses evaporative cooling tower for heat rejection. Water in cooling tower will be lost due to continuous evaporation, bleed-off and wind drift. The water lost will be replaced by water coming from the city water mains.

Water-cooled system with cooling tower

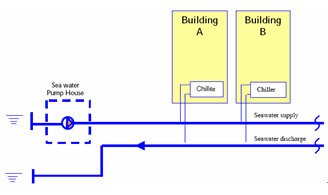

b) Central Sea Water Scheme

The air conditioning system uses seawater for heat rejection. A dedicated central sea water supply distributes seawater from the sea to the user building. The rejected warm seawater from the condenser will be returned to the sea via dedicated pipe.

Water-cooled system using seawater as heat rejection medium

c) District Cooling Scheme

Chilled water is produced by central chilled water plant. Individual user purchases chilled water for their building from the district cooling scheme operator and do not need to install their own chiller plants. For this scheme, a central chiller plant, a pump house and a central distribution pipeline network are required.

How it can save energy:

Water-cooled air conditioning system rejects heat depending on the ambient wet-bulb temperature rather than the dry-bulb temperature, so the refrigerant can be cooled to a lower temperature. This results in a better system coefficient of performance (COP) and thus more energy efficient.

How much energy can be saved?

A study commissioned by the Electrical and Mechanical Services Department (EMSD) showed that the District Cooling Scheme and Cooling Tower Scheme are more efficient than conventional air-cooled system as much as 35% and 20% respectively. This web page has hyperlinks which may transfer you to third-party website.For details of the study, please click here

EMSD has launched a pilot scheme on the wider use of fresh water for water-cooled air conditioning in non-domestic building in 2000 to encourage the use of water-cooled A/C.

Further sources of information:

EMSD website, Water-cooled air conditioning system: This web page has hyperlinks which may transfer you to third-party website.https://www.emsd.gov.hk/en/energy_efficiency/water_cooled_air_conditioning_system/

Reference

-

Roth, K. W., et al, 2002, Energy consumption characteristics of commercial building HVAC systems volume III: Energy saving potential, Building Technologies Program, Department of Energy, United States.

-

Architectural Service Department, Building Services Branch Circular No. 32 of 2006, Study Report on the Application of physical water treatment for scale control in waterside air conditioning system.